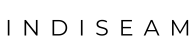

Where design meets functionality

Indiseam transforms your designs into production-ready digital patterns – ensuring perfect fit, streamlined sampling, and consistent quality across sizes.

- Digitally drafted base patterns

- Fit-focused pattern corrections

- Multi-size grading for consistent scaling

- Fabric-specific pattern adaptations

- Clear grainlines, notches, and seam allowances

- Editable formats for easy manufacturer handoff

Indiseam

How our pattern making service brings structure and precision to your designs

Precision-Crafted Pattern Making

Behind every flawless garment lies a perfectly made pattern. At Indiseam, we convert your creative vision into technical precision. Our pattern making service bridges the gap between concept and production, giving your manufacturer exactly what they need to bring your design to life — stitch by stitch, size by size.

Our expertise covers both manual and digital pattern development, optimized for accuracy, scalability, and manufacturing ease. Whether it’s your first collection or a new drop, we help ensure your styles fit right and are ready for production without repeated corrections.

The Art and Science of Garment Patterns

Pattern making isn’t just a technical task — it’s a blend of design understanding, garment construction knowledge, and production foresight. At Indiseam, we bring all three together.

Many brands underestimate the importance of pattern accuracy — until they face fit issues, inconsistent samples, or scaling errors. That’s where we come in.

We create well-balanced, digitized patterns that not only capture the structure of your design but also function perfectly across different sizes and fabrics. Our patterns are designed for industry use — easy to share, revise, and adapt across your manufacturing partners.

what you get

What’s included in our pattern making services?

When you work with Indiseam, you’re getting more than just patterns. You’re getting expert-backed templates that translate into efficient, consistent production — across samples and final units alike. Our service includes:

Development

Adjustments

Delivery

Development

Precision.

We create high-precision patterns using professional CAD software. These patterns are tailored to your specific designs and can be adjusted easily for different sizes, fabrics, or product types. Our digital approach ensures clean lines, symmetry, and ease of revisions — all while making your patterns production-ready from day one.

Adjustments

The Great Fit

A great pattern results in a great fit. We take into account not just measurements, but also body movement, drape, and garment construction techniques. After the first draft, we help refine the pattern based on sample feedback and provide corrections where needed — ensuring each piece fits exactly how you envisioned.

XXS-XXL

Once the base pattern is finalized, we provide accurate grading for your full size range. Whether you need XS–XL or custom sizing, we create proportionally balanced graded sets that maintain consistency in fit and styling across all sizes — a critical factor for brand trust and repeat orders.

Delivery

Digital & Printable

Receive your final patterns in industry-standard digital formats (such as DXF, AI, or PDF) that can be used across manufacturers and sampling partners. We also provide layout sheets and marker files upon request — perfect for efficient fabric cutting and waste optimization.

Creating Success

Why Our Pattern Making Works

Accurate Patterns. Smoother Production.

Our process ensures your patterns are made with an understanding of real-world production challenges. That means less trial and error, faster sample approvals, and a better final product — whether you're making 10 pieces or 10,000.

Expertise in Multiple Garment Categories

From structured blazers to stretchwear, we’ve developed patterns across fashion verticals. Our team understands how each fabric behaves, how fit preferences vary, and how patterns must adapt across styles.

Manufacturer-Friendly Outputs

We don’t just make patterns — we make them ready for use. Our files are optimized for easy digital handoff, and our pattern sheets come complete with grainline markings, notches, and construction notes for seamless stitching and minimal confusion.

The proof is in the numbers

Why paid search Ads can bring in the numbers

75%

of production delays are caused by pattern-related issues. Our professionally made patterns reduce that risk by delivering fit accuracy from the first sample.

90%

of clients who use both our pattern and sampling services report faster sample approvals and fewer size-related returns post-launch.

100%

of our patterns are made with scalable production in mind — from sampling to bulk runs, our files grow with your brand.

FAQ

FAQs About Pattern Making

Looking to learn more about our pattern making services for your brand? Browse our FAQs:

Pattern making is the process of creating a template (or pattern) for each part of a garment based on a design sketch. These patterns are used to cut fabric for sampling and production.

Yes — patterns are essential for making accurate samples. A good pattern ensures proper fit, style proportion, and consistency across all units.

Absolutely. Once we finalize your base pattern, we offer precise size grading to match your collection’s full range.

We provide digital pattern files in formats compatible with most manufacturers, such as DXF, PDF, or AI. Manual patterns and plot-outs can also be provided upon request.